Using Fabworks for Next Day Laser Cutting

In today's fast-paced product development landscape, rapid prototyping is essential for staying competitive. Fabworks offers next day laser cutting services that can significantly accelerate your prototyping process. By leveraging our advanced capabilities and streamlined workflow, you can bring your ideas to life faster than ever before.

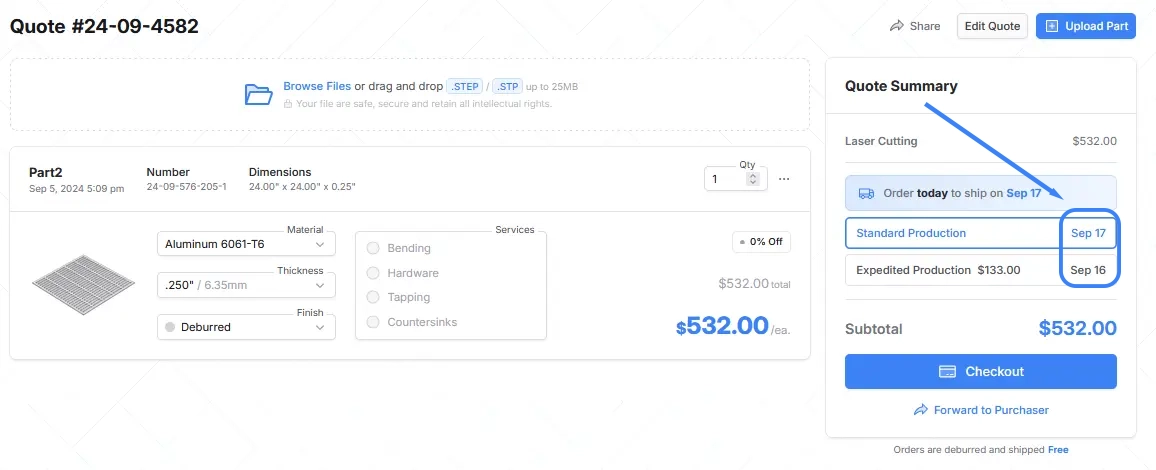

To help you plan production timelines Fabworks give an estimated ship date for your parts. This estimate will change depending on what you have configured, if you have bent parts, or parts with hardware this will increase your lead time. Feel free to play around with options and see how it changes your lead times.

The Power of Next Day Laser Cutting

When you're racing against the clock to validate a design or showcase a prototype to stakeholders, every hour counts. Fabworks' next day laser cutting service is designed to meet these tight deadlines without compromising on quality. Here's how you can make the most of our rapid turnaround times:

- Optimize Your Design: Before uploading your files, ensure your designs are finalized and optimized for laser cutting. This minimizes the need for revisions and helps us process your order quickly.

- Choose the Right Material: Fabworks offers a variety of materials that are ideal for rapid prototyping, including aluminum, steel, and stainless steel. Select the material that best suits your project's needs and timeline.

- Minimize additional services: Adding lots of hardware, tapping and countersinking will potentially increase lead times. Be sure to keep these requirements to a minimum.

- Leverage Our Instant Quoting: Our online platform provides instant quotes, allowing you to quickly assess costs and make decisions without delay.

- Opt for Rapid Production: When placing your order, select the "Expedited Production" option to prioritize your project in our queue.

Speed Up Bending: DIY

Consider using hand bends on prototype parts and doing the bending yourself. This will potentially cut days off the part lead time. Consider that ordering bent parts outside of our bending guidelines will potentially hold up the entire order. Consider splitting orders into bent and non-bent parts if you would be able to take advantage of the flat part arriving earlier. If you need help setting up a part to be hand bent, check out our article on the subject

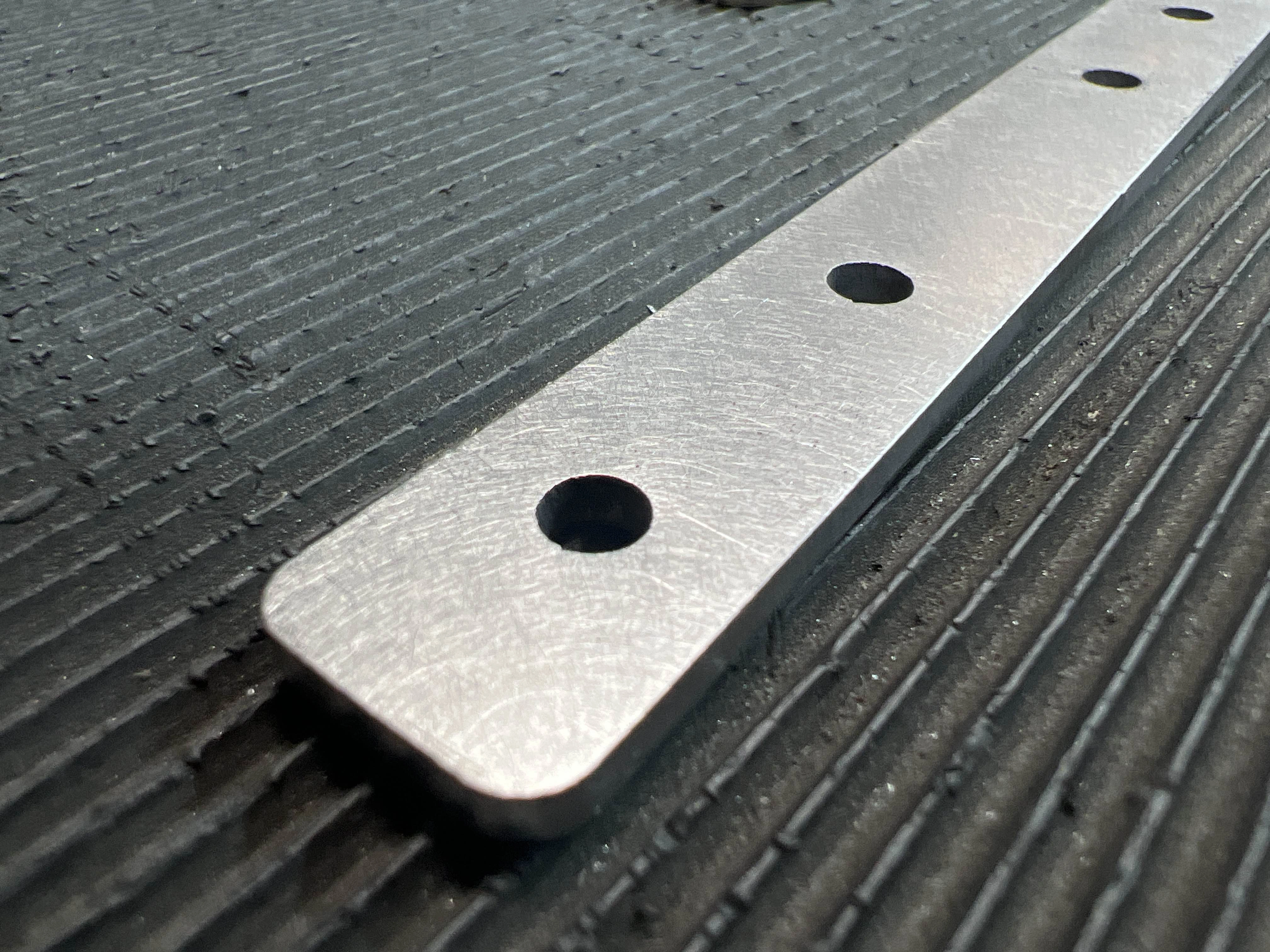

Speeding Up Turnaround: The Deburring Decision

One often overlooked aspect of the laser cutting process is deburring. While deburring provides a smooth, finished edge, it also adds time to the production process. For rapid prototyping, where speed is crucial, you might consider selecting "No Deburring" for your part finish.

Here's why:

- Faster Production: Skipping the deburring step can shave valuable time off the manufacturing process, potentially reducing turnaround.

- Suitable for Many Prototypes: For many prototyping applications, especially those focused on form and fit rather than final aesthetics, the slight roughness left by laser cutting is often acceptable.

However, it's important to note that deburring isn't just about aesthetics. In some cases, it can affect the functionality of your parts, especially if tight tolerances or smooth surfaces are critical to your design. Consider the needs of each part when deciding whether to disable deburring.

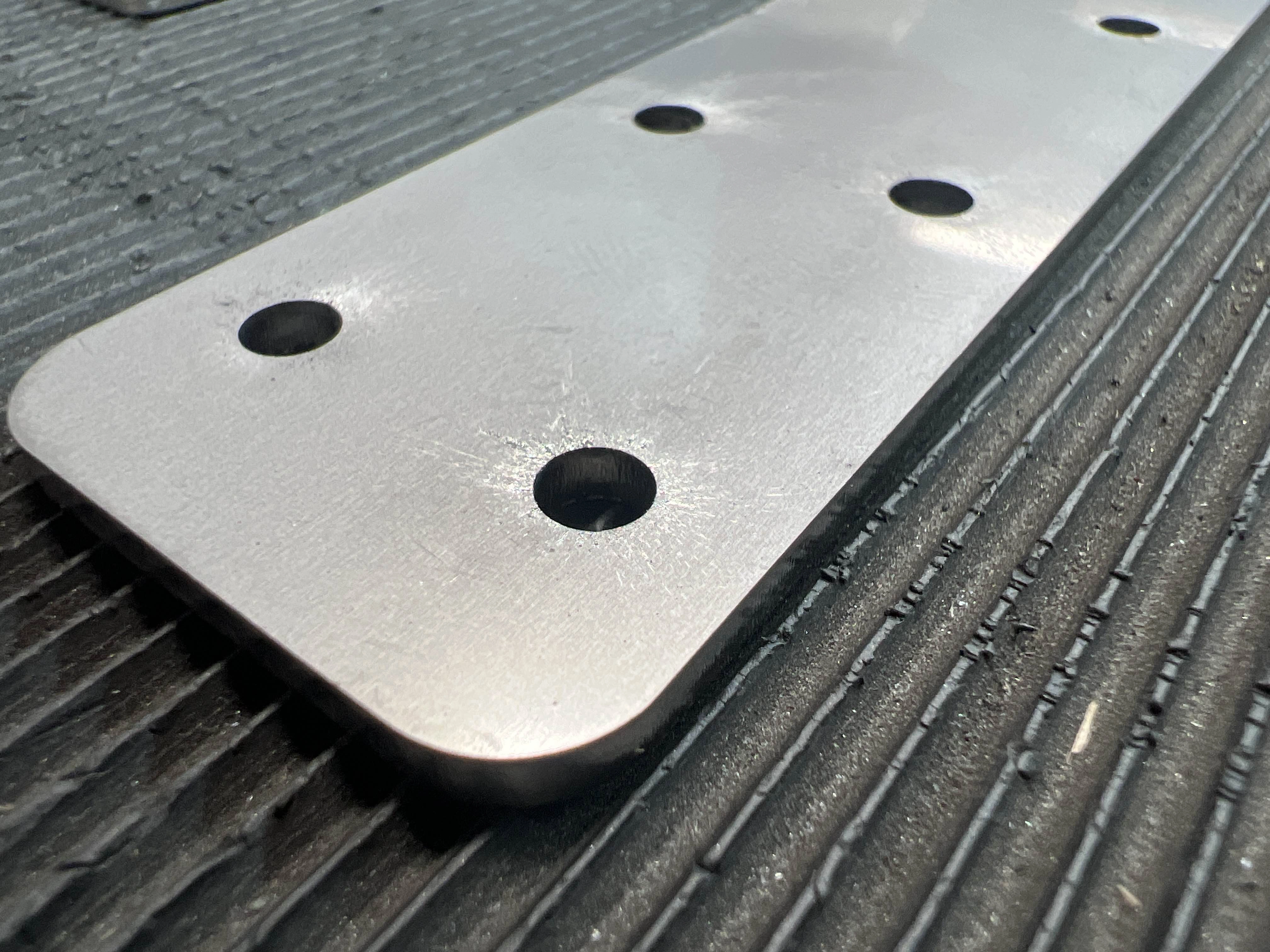

Deburred

Not Deburred

Maximizing Efficiency with Fabworks

Here are some practical tips to make the most of next-day laser cutting for your prototypes:

- Make sure your designs follow our specs for the best results. Our guide on pre-order checks has more details.

- If you're working on several pieces or versions, try to bundle them into one order. This can speed up processing and delivery.

- Got special requirements or a tight timeline? Just give our team a shout in the chat bubble. The more we know, the better we can help you out.

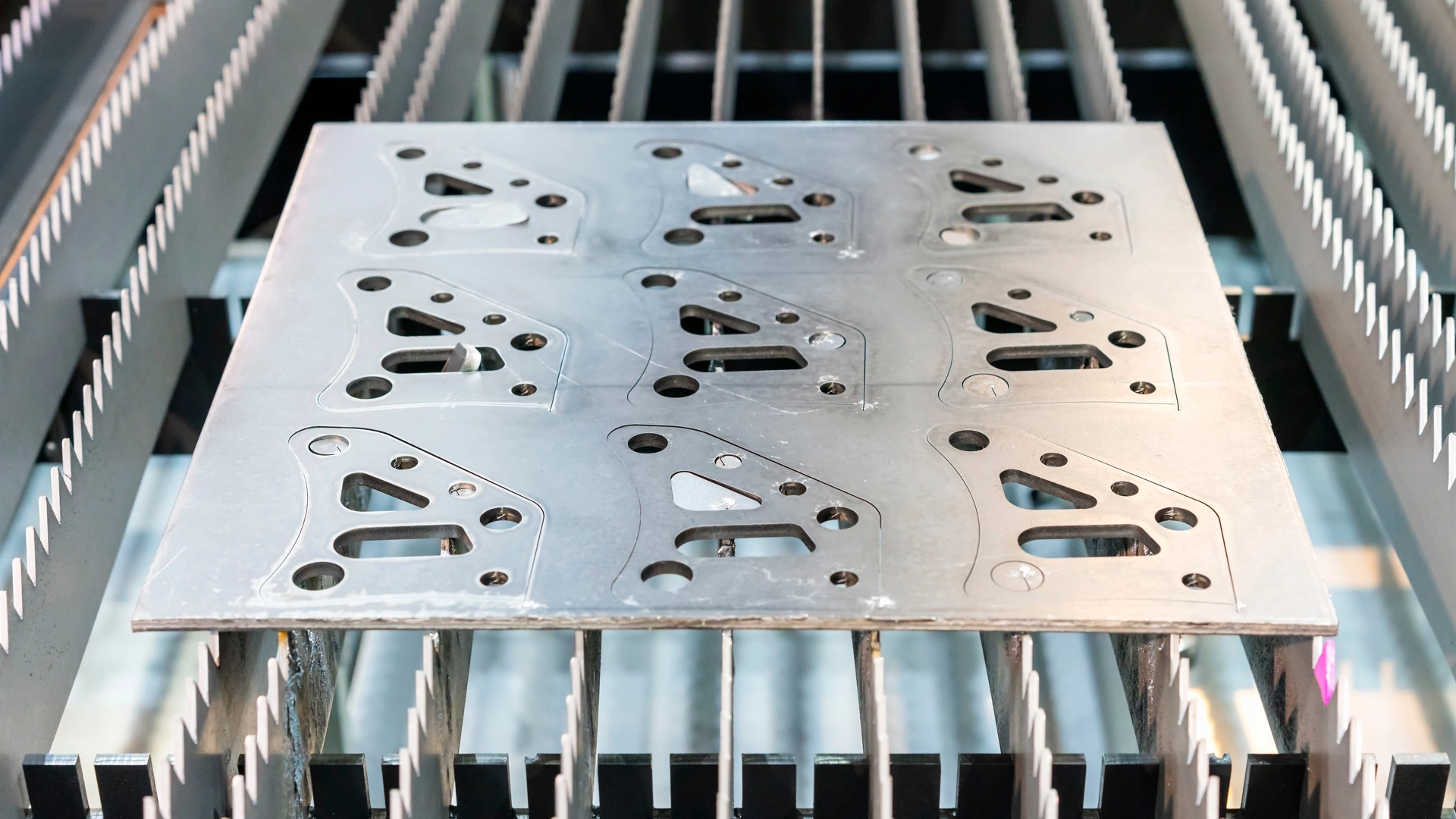

Beyond Prototyping: Scaling Up Production

Once you've perfected your prototype using our next day laser cutting service, Fabworks is equipped to support your transition to full-scale production. Our high-capacity laser cutting machine and additional services like bending and hardware insertion can accommodate larger orders while maintaining the quality and precision you expect.

By utilizing Fabworks' next day laser cutting services, you can dramatically accelerate your product development cycle. Whether you're a startup racing to market or an established company looking to innovate quickly, our rapid prototyping services provide the speed and flexibility you need to stay ahead of the competition.

Remember, in the world of product development, time is often the most valuable resource. With Fabworks as your partner, you can make every moment count, turning your ideas into reality faster than ever before.

Fast Track Your Project .

Seamless process, unparalleled precision, unbeatable speed. Turn your design into reality by beginning your journey with us today.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.