Hand Bending Guide

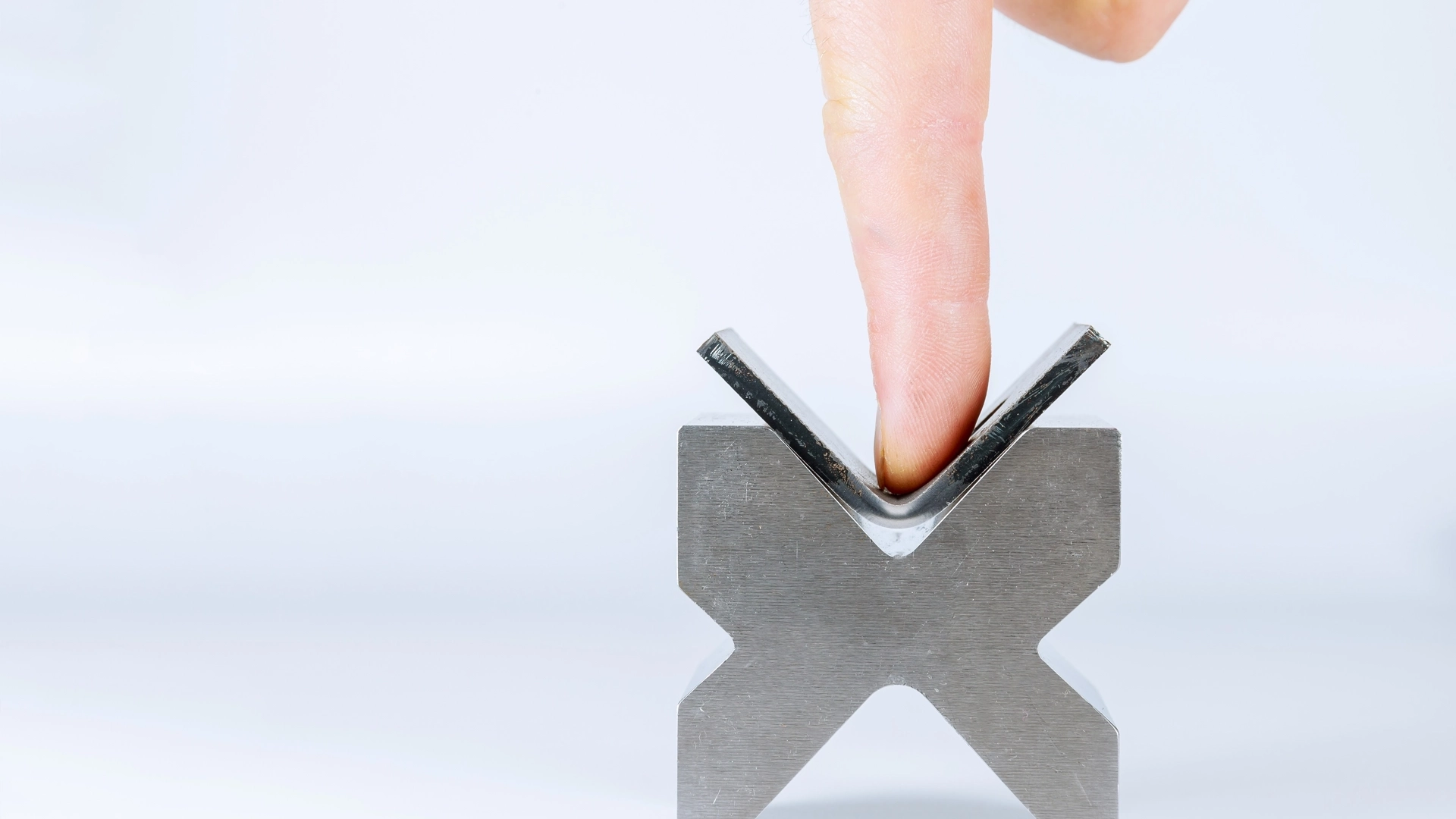

In the world of sheet metal fabrication, creating parts that can be easily bent by hand offers a range of benefits, from reducing manufacturing costs to enabling quick prototyping and on-site adjustments. There are various patterns you can use to make parts hand-bendable, but they all have one crucial element in common: they reduce the amount of material on the bend line. For the purposes of this guide, we will focus on using simple slots on the bend line to create easily bendable tabs. Material Considerations

When designing hand-bent parts, the most important factors to consider are the material type and its thickness. The choice of material significantly impacts the ease of bending and the final product's strength. Here are some key points to keep in mind:

Material Type: Softer metals like aluminum and certain grades of stainless steel are generally easier to bend by hand compared to harder metals like carbon steel.

Important:

Thickness: We typically recommend 1/16" (1.6mm) material thickness as an upper limit for hand bendability, but as thick as 1/8" will work with proper tab sizes, and making use of a vice to assist in bending. Attempting to bend thicker materials, such as 3/8" (9.5mm) steel, by hand will be extremely difficult and may result in inconsistent bends.

Design Process The process of designing hand bends is relatively straightforward:

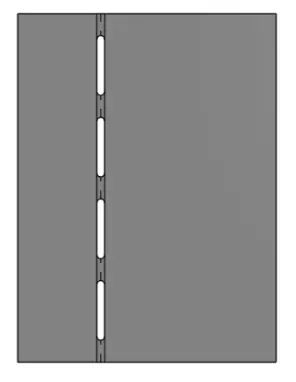

Create your sheet metal part as normal in your CAD software. Identify the bend lines where you want to create hand-bendable sections. Add slots or perforations along these bend lines on the flat pattern. Adjust the size and spacing of the slots based on your material properties and desired bend characteristics.

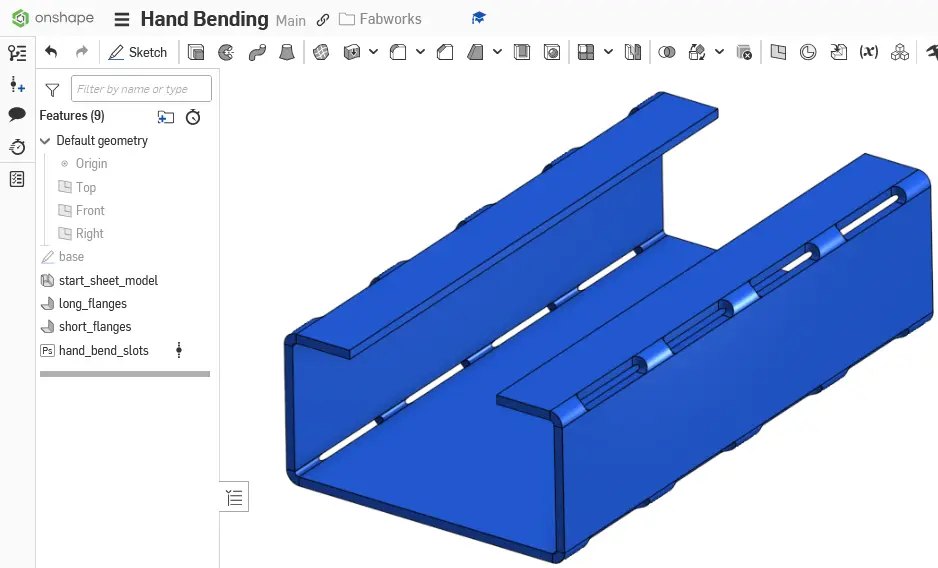

Making hand bends with Onshape

One of Onshape's most powerful features is the ability for anyone to create custom tools to manipulate parts. This featurescript allows you to add hand bend slots to sheet metal models very easily, by just giving some parameters and selecting your bend lines.

How to size your slots.

- The width of each slot should be at least half the thickness of your material.

- The width between slots should atleast be the thickness of the material, if you make the tabs larger it will increase the strength of the bend, but also make it harder to bend in the process.

Incorporating hand-bendable features into your sheet metal designs can greatly enhance the flexibility and usability of your parts. By understanding the principles behind hand bending and utilizing tools like Onshape's custom FeatureScript, you can easily create parts that can be adjusted on-site or used for rapid prototyping. As with any design process, it's important to test your designs and iterate to find the optimal parameters for your specific applications.

Tube Lasers Explained

A brief overview of tube laser technology.

Fast Track Your Project .

Seamless process, unparalleled precision, unbeatable speed. Turn your design into reality by beginning your journey with us today.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.