Steel vs Aluminum

Aluminum and steel are two great materials to use in many different applications. With the many different alloy varieties, it can be difficult as a manufacturer to find the perfect material that fits your needs, while also fitting in your budget. Breaking down the differences between these two alloys and their grades is a great starting point.

Comparing Aluminum and Steel: What Sets Them Apart?

These two metals are very different compositionally. Aluminum is mainly alloyed with magnesium and chromium with other metals being used to give different alloys special properties. Steel is mainly a combination of iron and carbon.

There are many different types of grades of steel and aluminum, making them better for certain Applications. Fabworks offers three optimal aluminum alloys, 5052-H32, 6061-T6, and 7075-T6.

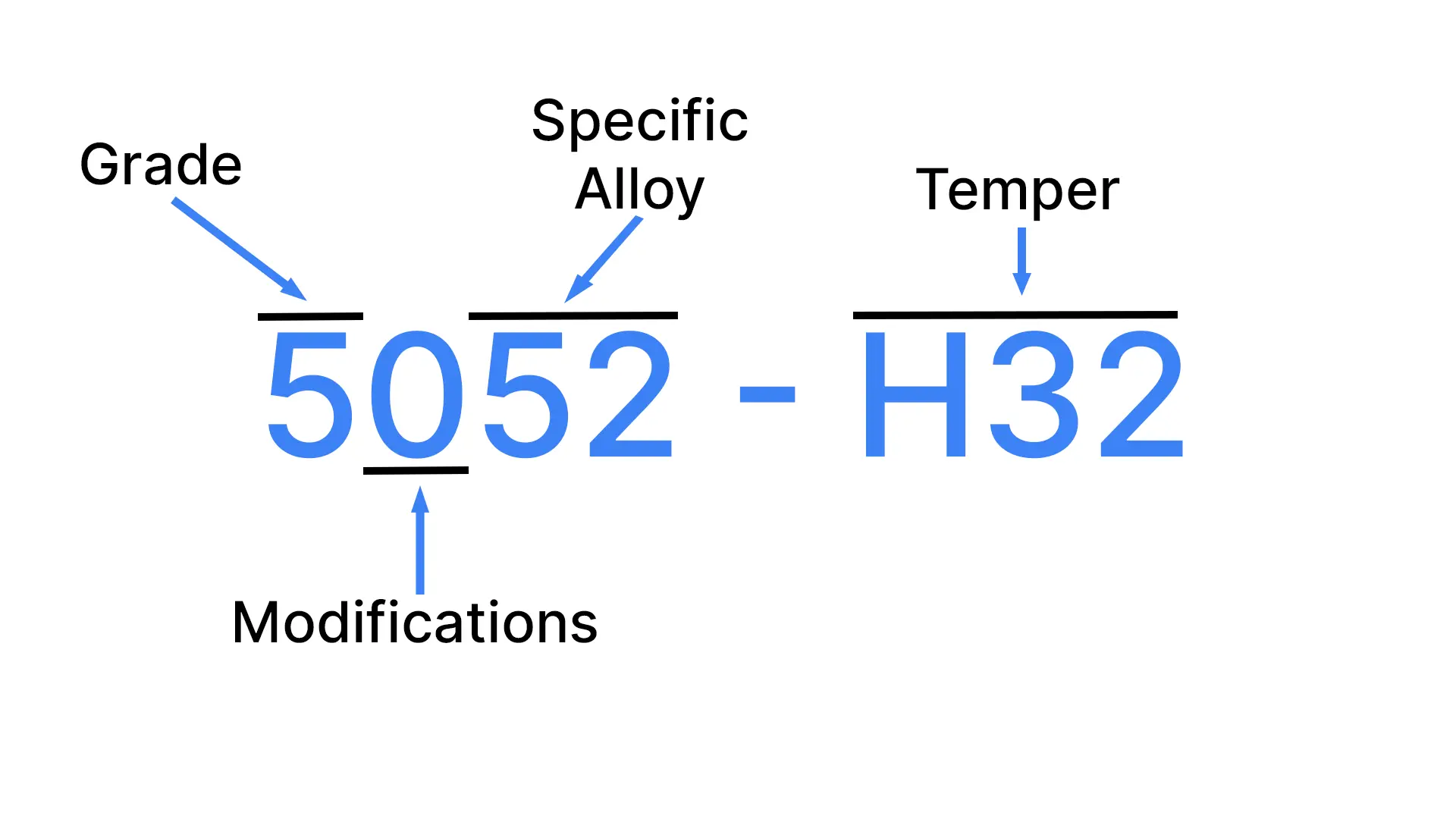

The first number in the alloy name corresponds to the grade of aluminum, and the main other material in the alloy. The second number in the alloy name is used to indicate any modification done to the alloy, if no modifications were made it is left 0. The next two numbers in the first half of the name represent the specific alloy within the grade of aluminum. The second half of the alloy name denotes the temper, which adds additional properties to the aluminum. T6 denotes the aluminum was heated to a high temperature, to fully dissolve the elements in the alloy, and then artificially aged for added strength and hardness. Since Grade 5 Aluminum is unable to be heat treated like 6 and 7 Grade aluminum, it is instead strain hardened and heated to low temperatures.

Steel on the other hand has more versatile combinations, which can make it hard to choose from if you do not know what you want or need. While there are countless steel alloys in existence with their own special properties, there are some alloys suited for a wide range of applications. Fabworks carries 1008, and A36 steel due to their wide range of desirable properties.

1008 steel is great for applications where extreme strength is not a priority. It is very easy to form and weld, making it easy to work with. A36 steel has a higher tensile strength than 1008 steel, while still maintaining weldability, and formability.

Key Differences and Advantages

Aluminum and steel vary in grades, tempers, and processes in which they can be produced in. This gives them different strengths, weights, and corrosion resistances. It can also change how easy they are to work with. We can start with the most basic determining factors for most clients besides cost, which is strength and weight.

Strength

Strength can be one of the most important factors when it comes to choosing which material to use. Depending on the quality and type of aluminum and steel, they can provide the same strength properties. Aluminum can be stronger than steel in some instances. However, typically steel is stronger than aluminum.

Strength to Weight ratio

With strength in mind, steel may be stronger in most aspects, however aluminum comes on top in the weight to ratio battle. If you had two parts that were the exact same in size and shape, aluminum will be a third of the weight steel is. This makes it extremely strong in the comparison of strength-to-weight. This is an example of how great it can be for applications in which weight is a determining factor. This can mainly be seen in the aerospace Industry which sees the need for lighter yet strong materials.

Durability

Durability can vary due to the environmental conditions that the material is put in, as well as the use case. Aluminum is a softer metal, which makes it weak to constant rubbing or abrasion as it can eat away at the aluminum. Its fatigue strength is cut in half compared to steel. Steel excels in shear strength and shear modulus compared to aluminum, making it better for when there will be constant high stress on the parts in the application.

Corrosion Resistance

Most steel is extremely corrosive, which can reduce fatigue and shear strength. This is where aluminum shines, as it naturally has excellent corrosion resistance. Aluminum still oxidizes and forms an oxidation layer like iron. Although iron oxidation can be brittle and flakey, aluminum oxidation does the exact opposite, it acts as a shield for the aluminum, providing aluminum with an upper hand in longevity in highly corrosive environments. However, if you mix the right alloys into steel, it can provide the same corrosion resistance as aluminum, this alloy is usually called stainless steel. Stainless steel usually has chromium-nickel in it, to give it the layer it needs for that corrosive resistance. In light of this, stainless steel provides excellent properties comparable to aluminum for which stronger shear and fatigue strength is needed in those corrosive environments.

Thermal Conductivity and Characteristics

Steel and aluminum both have a high thermal conductivity, aluminum though tends to conduct it better than steel. This makes it a great material for transferring heat, and is commonly used in heat sinks. Another important fact is aluminum has a lower melting point, while steel has a significantly higher melting point compared to aluminum. This makes steel a better material for implementation in machines or appliances found in foundries.

Magnetic Properties

Aluminum being a non-ferrous material which means it lacks the element Iron, makes it non magnetic. Due to its non magnetic characteristic, it makes a great electromagnetic shielding. This makes it great for electrical enclosures that house electronics that can be affected by external frequencies and magnetic fields. On the other hand, steel is a ferrous material as it is a composition of Iron and carbon. This makes it extremely susceptible to magnetic fields. This makes it great for applications where the magnetic field susceptibility is desired. They are used in the production of electrical motors, transformers, and many other electromagnetic components that need its efficient magnetic properties. In spite of this, it's important to note that not all steels are the same in their magnetic properties. For example most stainless steels with their addition of chromium-nickel in its composition, counteracts the ferrous materials magnetic properties, making it weak or completely non magnetic.

Machinability and Formability

Aluminum and steel are both easily formable and machinable depending on the grade. Aluminum is typically easier to machine and form compared to steel. As mentioned earlier, aluminum is a softer metal, this makes it easier to bend, and form into what the customer wants. This also makes it easier to machine into desired parts, however aluminum requires more specific tools and expertise when it comes to welding.

Considering this, steel is still a relatively easily formed material, and can also be easily welded. The only type that will be difficult to form is stainless steel. Stainless steel, due to Its composition is extremely hard to form and bend. Fabworks Sheet Metal Bending Service can alleviate the challenges of forming stainless steel.

Cost Considerations

In spite of everything, there is still one major determining factor that can change a clients decision on what to buy, and that is cost. Even though some steel is optimal for some exterior of an appliance, alternatives can be provided, like 1008 Steel that is powder coated can provide similar environmental resistance comparable to stainless steel at a cheaper cost, as not every application will need what stainless steel has to offer. The same can be said about Aluminum, Some instances 6061 will do the same job as 7075, and for cheaper It all comes down to comparing what numbers you truly need and what each material has to offer.

Applications and Implementation for your needs

We understand that choosing the perfect material for your part can be daunting. To make the decision easier, we’ve put together a list of recommended materials for every standard use case. Let us guide you to the right choice with expert recommendations tailored to your needs.

| Use Case | Recommended Material |

|---|---|

| Structural Parts | A36 Steel or 7075-T6 Aluminum |

| Marine Environment | 6061-T6 Aluminum or 304-2B Stainless Steel |

| Abrasive or High Wear Applications | A36 Steel |

| Food Processing Equipment | 304-2B Stainless Steel |

| Decorative Parts | 304-2B Stainless Steel or 6061-T6 Aluminum |

| Cutting Edges | A36 Steel or 304-2B Stainless Steel |

| Heat Transfer | 6061-T6 Aluminum |

Effortless Manufacturing Starts with Fabworks

When choosing a material for your manufacturing or prototyping phase, Fabworks is here to assist you in producing high-quality parts with unmatched precision. Our expertise ensures that any potential issues are minimized to one side rather than affecting the entire process. With Fabworks, you can trust that your custom cut stainless steel and aluminum parts will meet the highest standards, allowing you to focus on innovation and performance without worry.

Laser Cutting Kerf Explained

Find out what the term kerf width refers to in laser cutting and how it affects manufacturing and design processes.

How to Pick the Best Material for your Laser Cut Project

Learn about the strengths, weaknesses, and ideal applications of stainless steel, aluminum, mild steel, copper, and brass.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.