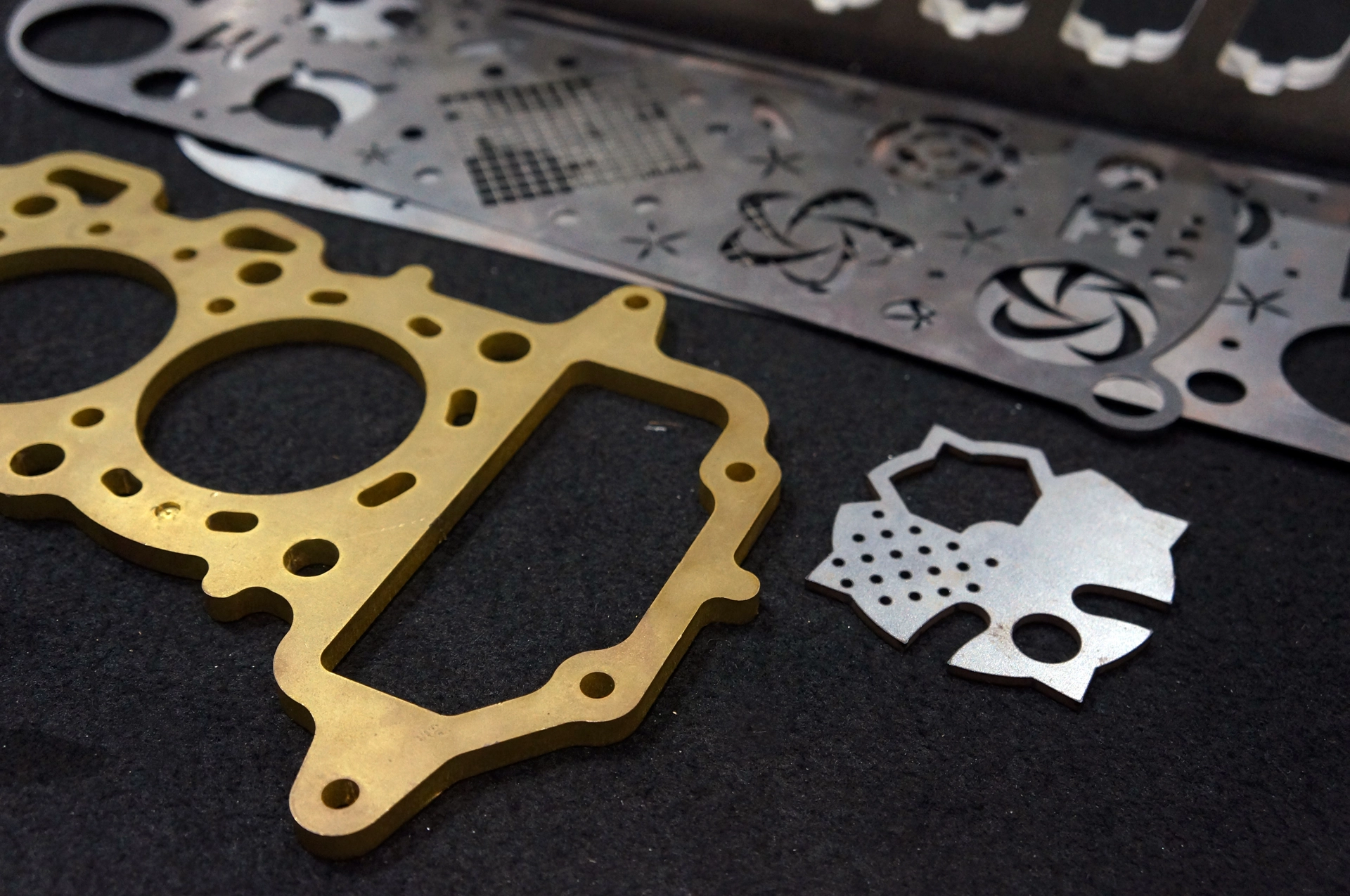

How to Pick the Best Material for your Laser Cut Project

Making the correct choice of materials is a crucial part of the design process. The materials that a part is made from affect its appearance, performance, lifespan, and most importantly, cost. Materials also have an impact in other areas as well, such as recyclability.

When it comes to choosing between metals, some of the most important things to consider are strength, weight, hardness, resistance to corrosion, and cost. Different metals offer a different range of qualities, and it’s important to look at things carefully.

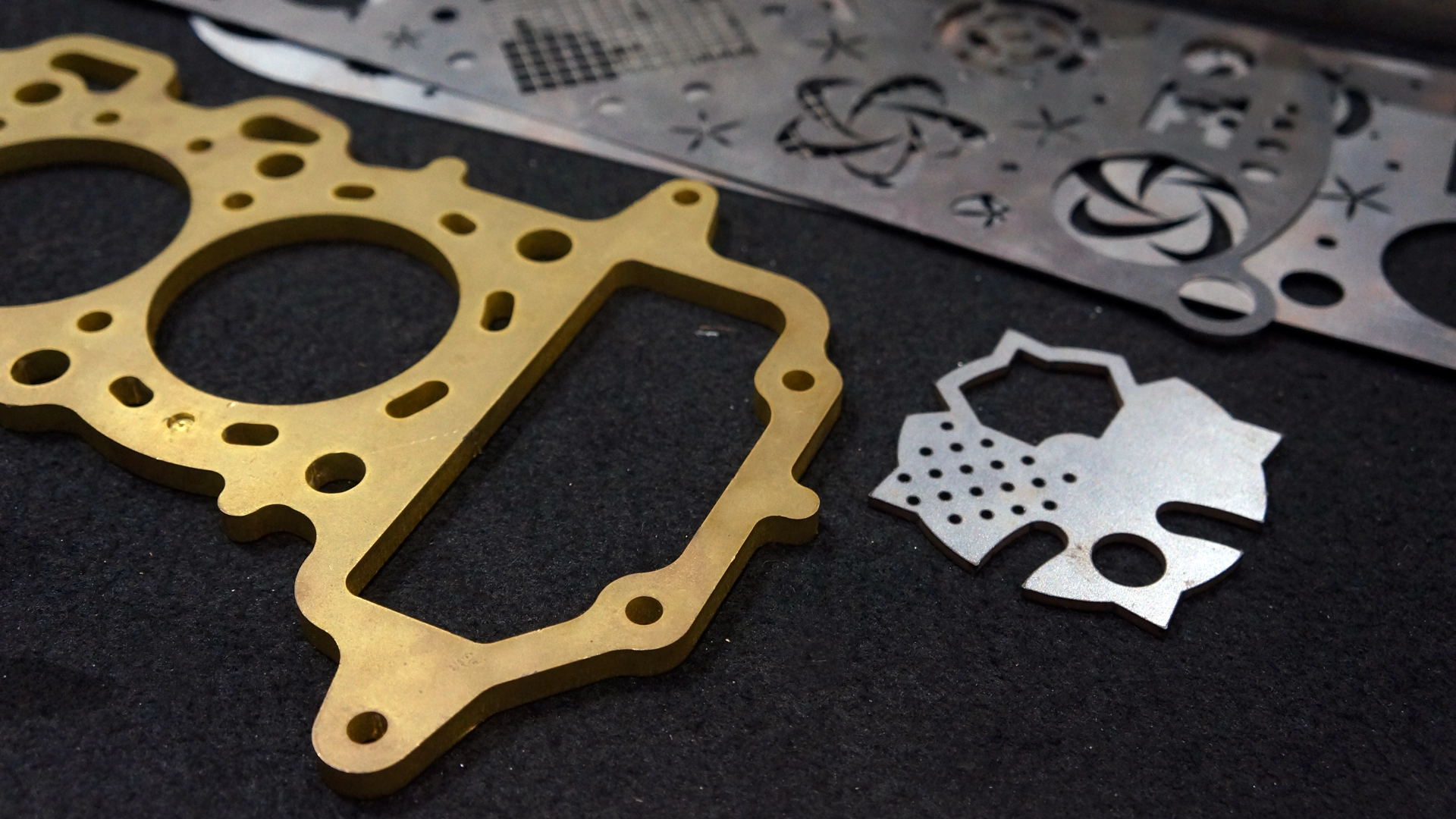

Fiber laser cutting works well with metals. While there may be some differences in terms of production efficiency between different metals, all the metals discussed in this article can be cut with a laser cutter. They’re also available through Fabworks’ laser cutting service.

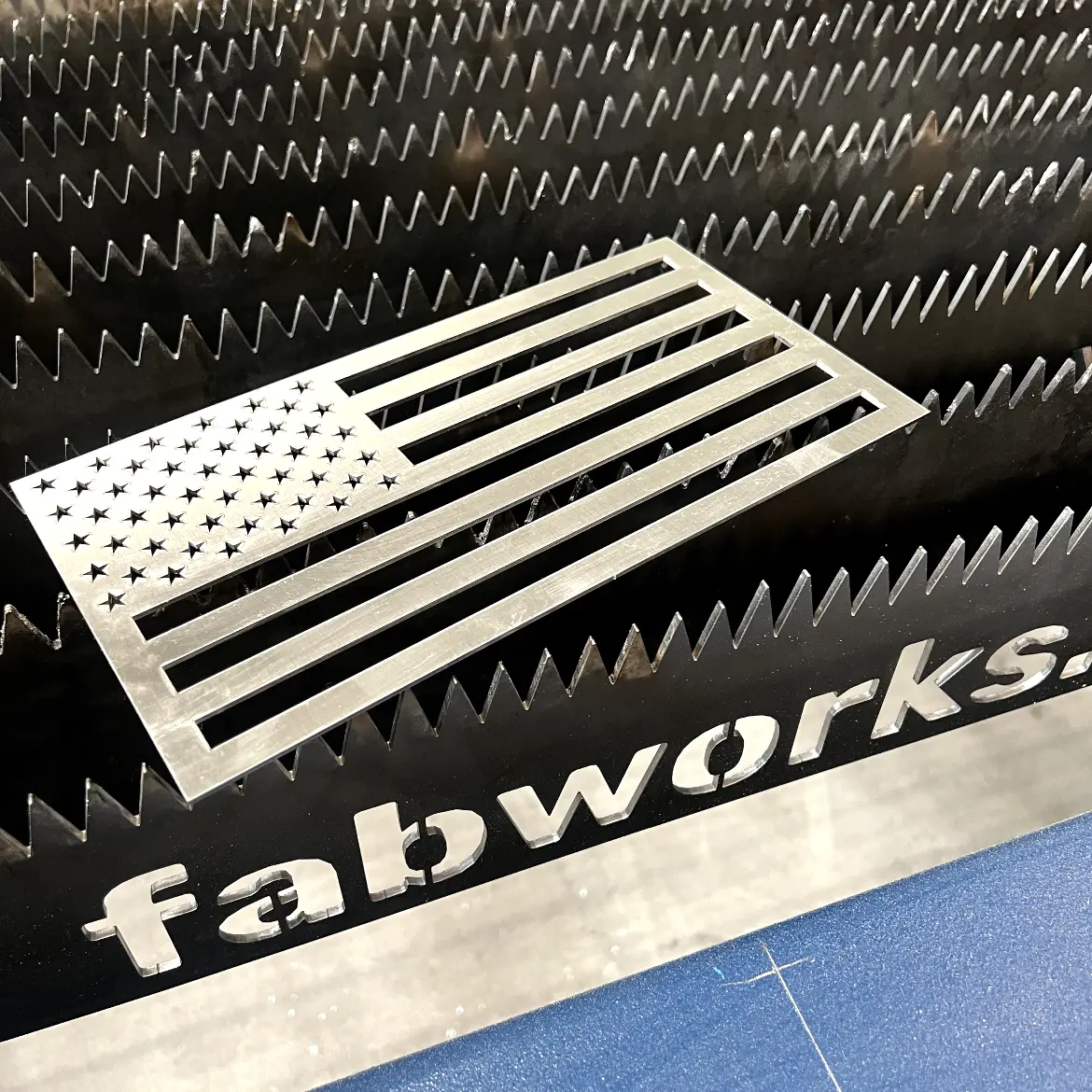

Stainless Steel

Stainless steel is a versatile metal that excels in strength and corrosion resistance.

These qualities of strength and corrosion resistance are achieved by adding chromium to the standard iron-carbon alloy found in mild steel. Stainless steel also offers good weldability and formability, and it responds well to processes such as brazing, polishing, and buffing. In addition to this, stainless steel is also very hard, resisting surface damage through impact.

The main disadvantage of stainless steel is its weight and higher cost. Welding and some other manufacturing processes can also be more difficult than with other materials.

Stainless steel is well suited to laser cutting. Laser-cut stainless steel parts have a smooth finish that doesn’t necessarily require any extra finishing processes.

Applications for Laser Cut Stainless Steel

The versatility that stainless steel offers makes it suitable for a number of applications, and this metal is found in almost any product type. However, its strength and corrosion resistance make it particularly well suited to:

- Corrosive environments

- High-stress applications

Industries that often use stainless steel are the aerospace, automotive, construction, cookware, and medical industries.

Products that are often made of stainless steel are:

- Cookware and kitchen products

- Airplane parts requiring high levels of strength

- Roofing and cladding

- Products in the marine environment

- Vehicle parts

- Agricultural equipment

At Fabworks, we offer 304-2B stainless steel that gives great strength, resilience, and corrosion resistance while being easily machined and formed.

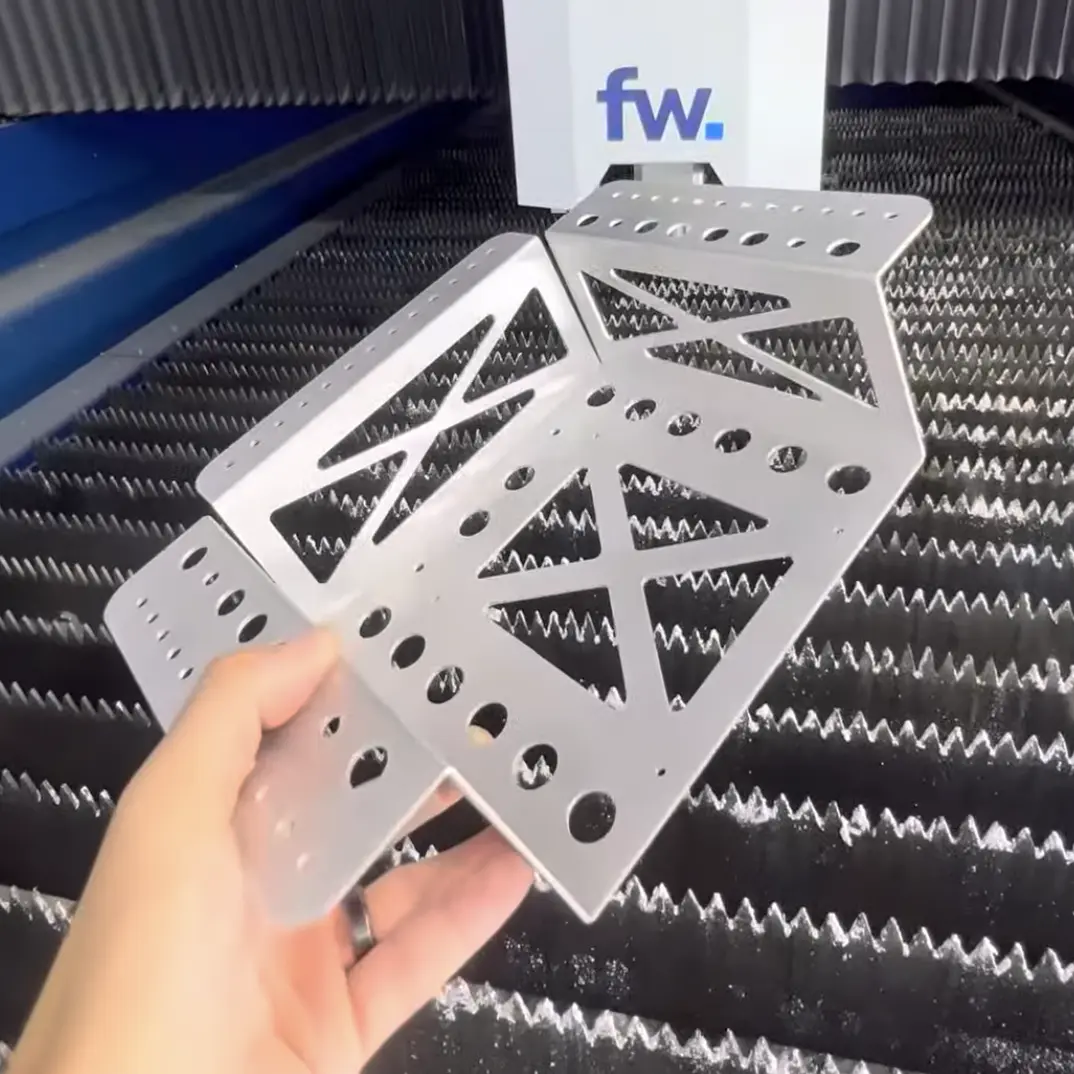

Aluminum

Aluminum is another versatile metal. It’s best known, however, for its low cost, durability, and light weight and also for being easy to form and machine. In addition to these qualities, aluminum also offers good thermal and electrical conductivity. Where additional corrosion resistance is required, aluminum can also be anodized. Through anodization, an oxide layer is formed on the surface, protecting the material from corrosion.

The main disadvantages of aluminum are its low mechanical strength and lower levels of corrosion resistance compared to other metals.

Although the reflectiveness of aluminum sometimes causes issues with laser cutting, it generally cuts very well under a laser cutter.

Applications for Laser Cut Aluminum

Aluminum is a versatile metal, and it can be found in a very wide range of products. However, it excels in being:

- Light weight

- Low Cost

Industries that often use aluminum are the automotive, electrical, aerospace, chemical, construction, and cookware industries.

Some common applications of aluminum are::

- Airplane parts

- Automotive parts

- Food packaging

- Electrical casings and electrical products

- Construction equipment

At Fabworks, we offer 5052-H32, 6061-T6, and 7075-T6 aluminum.

Here’s a quick rundown of the different qualities of these alloys:

- 5052 - Highly bendable

- 6061 - Increased strength, and unbendable

- 7075 - Strongest in strength, and unbendable

For more detailed information you can look at our information page.

Mild Steel

Mild steel is a cost-effective metal that has a high level of strength and hardness. It’s well suited to applications where corrosion and aesthetics are not an issue.

Mild steel is formed from a simple alloy of iron and carbon. There are three main types, and these are hot-rolled steel, cold-rolled steel, and hot-rolled pickled and oiled steel. To produce cold-rolled and hot-rolled pickled and oiled steel, basic hot-rolled steel is subjected to additional processing.

As well as being high-strength and hard, mild steel can also be machined and formed easily in production. It is also very weldable and can be given finishes to improve its aesthetics.

The main disadvantages of mild steel are its weight, and low resistance to corrosion.

Applications for Laser Cut Mild Steel

Mild steel can be found in many applications, and it excels in applications where:

- Strength and hardness are needed

- Aesthetics are less important

- Costs need to be reduced

It is also often found in applications where corrosion is less of an issue. It is possible to finish mild steel, however, to provide corrosion resistance.

Industries that commonly use mild steel are the construction, automotive, agricultural, furniture, and home appliance industries.

Products that are often made of mild steel are:

- Construction beams

- Vehicle frames

- Desks and office equipment

- Kitchen appliances

- Lighting products

At Fabworks, we offer 1008 cold-rolled steel and A36 hot-rolled pickled and oiled steel. Find out more about what both of these alloys offer on our information page.

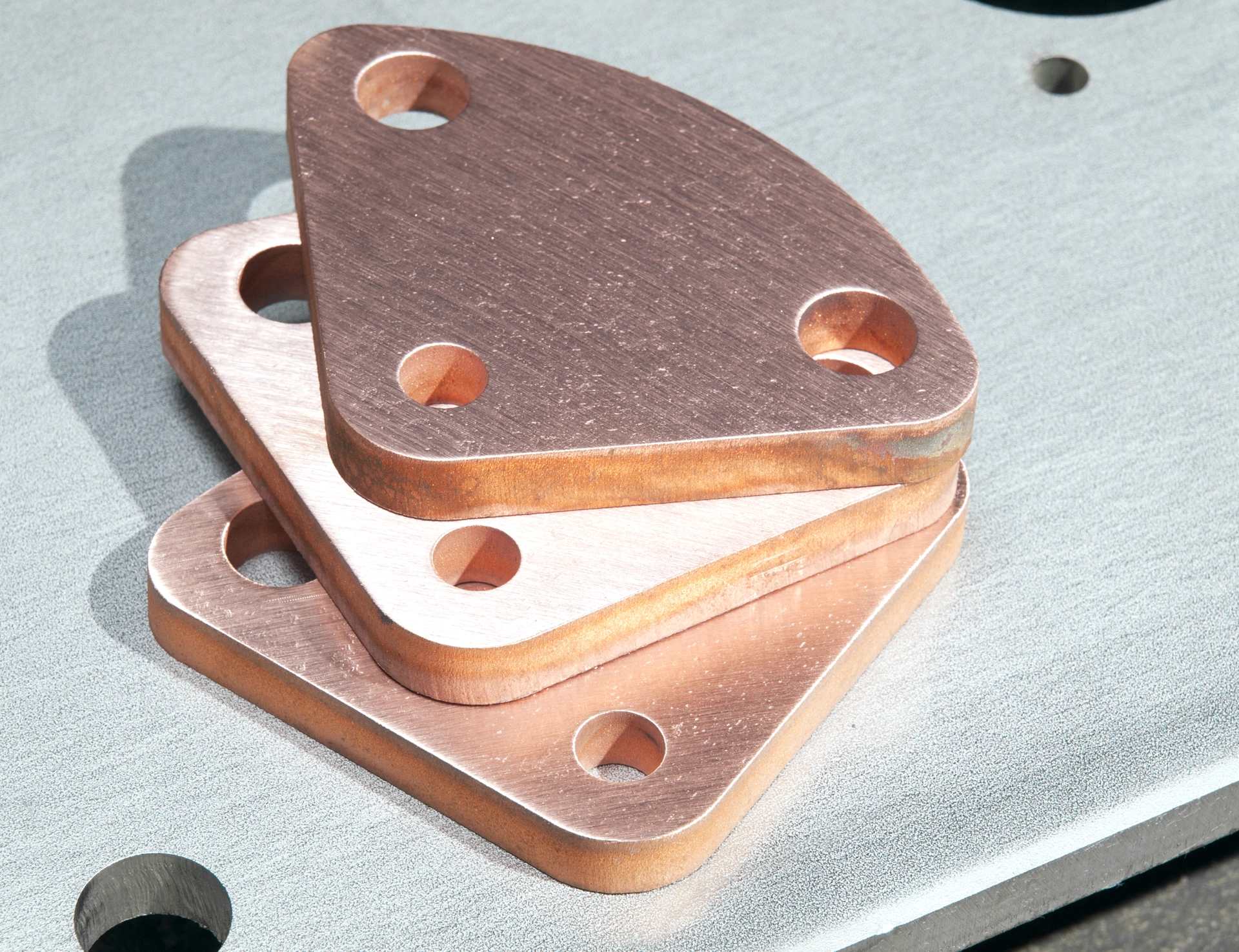

Copper

Copper offers great aesthetic appeal but also has physical properties that make it well-suited to certain applications.

Copper is electrically conductive and corrosion resistant, and these properties make it excel in outdoor applications and when electrical conductivity is needed. Copper can be used for architectural features or garden equipment, for example. Otherwise, it may simply be used to provide an electrical connection.

As well as being electrically conductive and corrosion resistant, copper is also hard-wearing and malleable. In addition to the qualities mentioned, copper is also anti-microbial, making it useful in kitchenware applications.

Copper is not available through the standard Fabworks interface, it is only available via custom quote.

Brass

Brass is formed from an alloy of copper and zinc. The zinc is added to enhance the strength and ductility of the material and also to reduce its friction point.

The increased strength of brass makes it suited to applications where it will be put under stress. As with copper, brass can be used for architectural features and ornaments. It can also be used, however, for applications such as hinges, doorknobs, or musical instruments, where it is subject to stress while also needing to look good.

Brass is also malleable and easily formed and machined in production. It is also weldable and easily soldered.

Brass is not available through the standard Fabworks interface, it is only available via custom quote.

Summary

Different metals offer different qualities, and it’s important to make sure you use the right metal for your part. Take your time to read through the information we’ve provided in this post carefully.

For more information, you can also visit our materials information page.

Fabworks

If you want to find out how much it will cost to produce a product or part you already have designs for, you can upload your designs to Fabworks and get an instant quote. We’d also be happy to discuss your choice of metal for your laser-cut parts with you. Get in touch with us here.

Comprehensive Guide to Stainless Steel

Stainless steel is a versatile and widely used alloy known for its corrosion resistance and durability.

Fast Track Your Project .

Seamless process, unparalleled precision, unbeatable speed. Turn your design into reality by beginning your journey with us today.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.