Sheet MetalBending Service.

Upload your 3D STEP files for automatic bending configuration. Choose from our extensive selection of materials.

or drag and drop

.STEP .STP or .DXF up to 4.5MB

Your file are safe, secure and retain all intellectual rights.

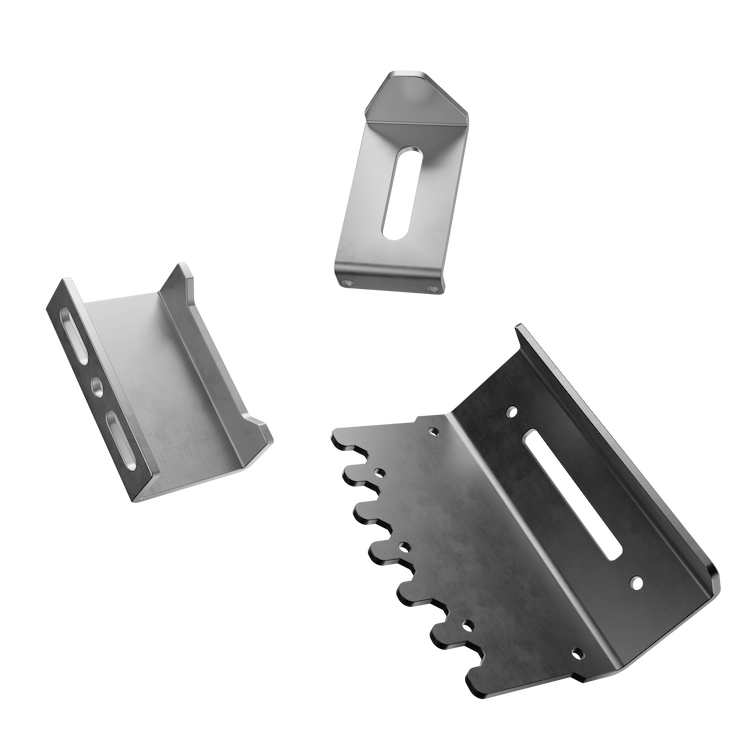

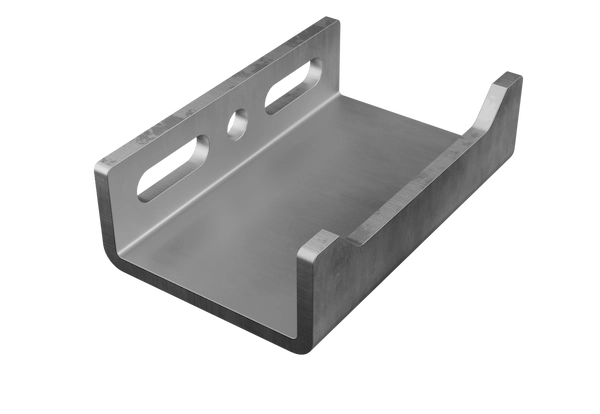

Precision Sheet Metal Bending.

Precision isn't just a goal, it's a guarantee. Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications.

- State-of-the-Art Equipment

- Fabworks utilizes the latest in CNC bending technology for consistent accuracy and repeatability.

- Expert Team

- Our skilled technicians bring precision to every project, everytime.

- Extensive Capabilities

- 1-135 degree bends | +/- 1 degree angle tolerance | +/- .015" length tolerance

Industry Standard Materials.

Select from a refined list of high performing materials, expertly picked to give you the best laser cutting and bending results.

Instant Pricing and Lead Times.

Our commitment to transparency means you get fast, accurate quotes and realistic timelines for your projects. We understand the importance of planning and budgeting, and we ensure you have all the information you need, instantly.

- Immediate Quotes

- Get instant pricing for your bending projects with our user-friendly online platform. Just upload a STEP file.

- Transparent Leadtimes

- We provide clear and honest timelines, so you can plan your projects with confidence.

- Efficient Processes

- Easy one click upload for quick and accurate estimations, ensuring your project stays on track.

Pair With These Other Services

Along with our metal Bending, you can add additional services to your parts. It's everything you need to take your idea from concept to reality, all in one place.

No Order Minimums.

At Fabworks, we believe in serving all your bending needs, big or small. With no minimum order requirements, we're here to support a single prototype or a large production run. We're committed to providing the same high level of quality on all order sizes.

- Flexibility for All Projects

- From one-off prototypes to large batches, we accommodate orders of any size.

- Ideal for Prototyping

- Test your designs without the commitment to large quantities.

- Cost-Effective Solutions

- Get exactly what you need, when you need it, without worrying about meeting minimum order quantities.

Customer Reviews.

See what others have to say about our online sheet metal and laser cutting service.

Max G.

When I ordered a couple of parts for a custom project I was greatly satisfied by the speed and quality of my order.

Michael P.

These guys are fantastic, lightning quick service and always exactly what we need. Turn around time for simple cut and bend has been just a few days for us and pretty cost competitive.

Geoff D.

Ordered for our FTC team… Cut 1/8” aluminum parts came out better than expected, and faster than expected. At roughly half the cost!

Jeremy G.

Excellent service all around. Sleek website makes placing and configuring orders pretty seamless. Parts shipped quickly and arrived packaged nicely.

Tahoma R.

Our FIRST Robotics Team has used Fabworks for a couple of our off-season projects. Impressed with their prices, communication, quality and speed.

Dulaney R.

Fantastic experience ordering parts through Fabworks! Amazing lead time and customer support has made a huge difference for our team.

Frequently Asked Questions.

Get your questions answered, if you can't find something your looking for, check out our resource center.