What is K-Factor?

When it comes to sheet metal bending, precision is everything. One of the most important factors in achieving accurate bends is understanding and applying the correct K-factor. But what exactly is K-factor, and why does it matter? Let's dive in.

What is K-factor?

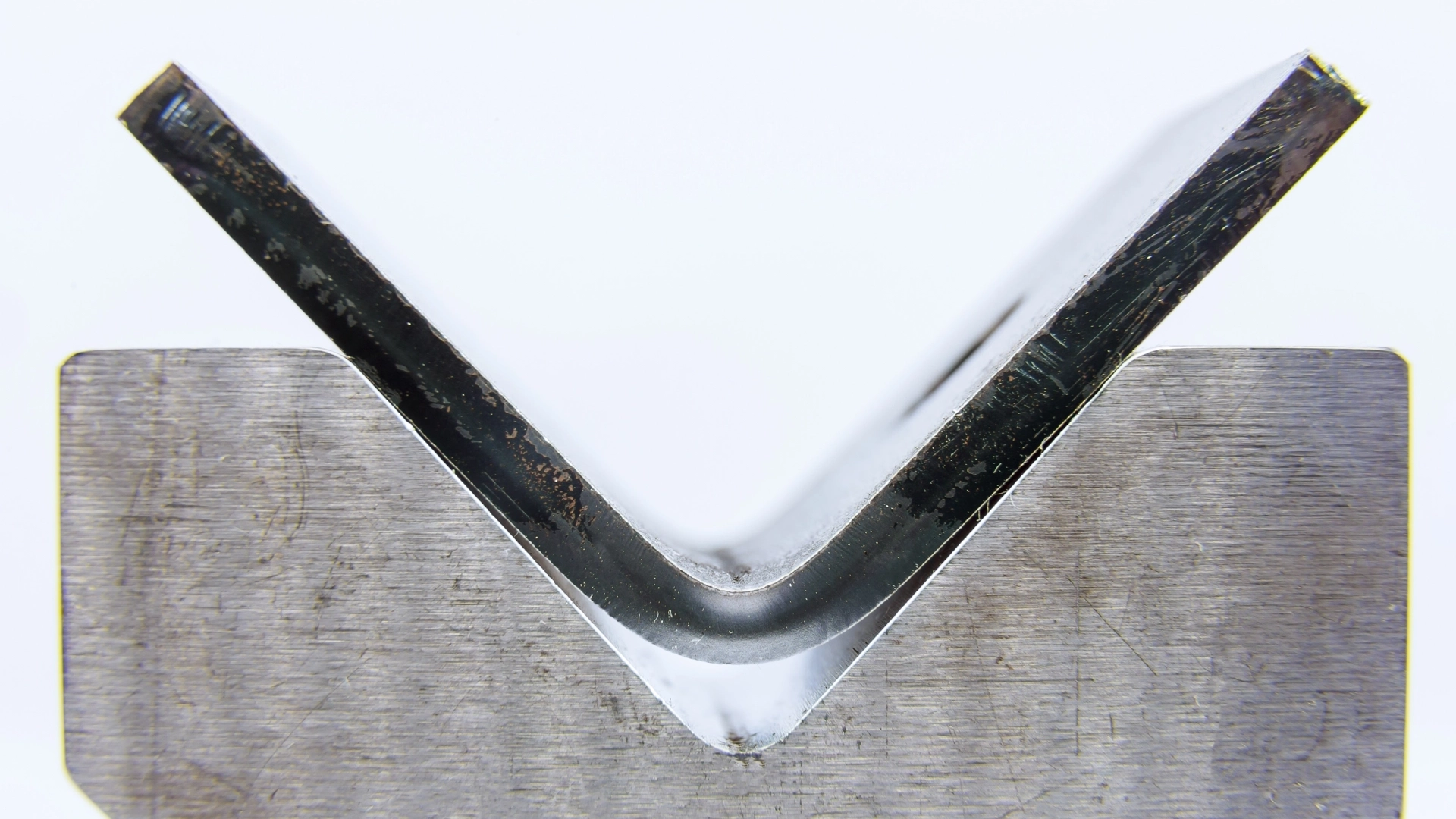

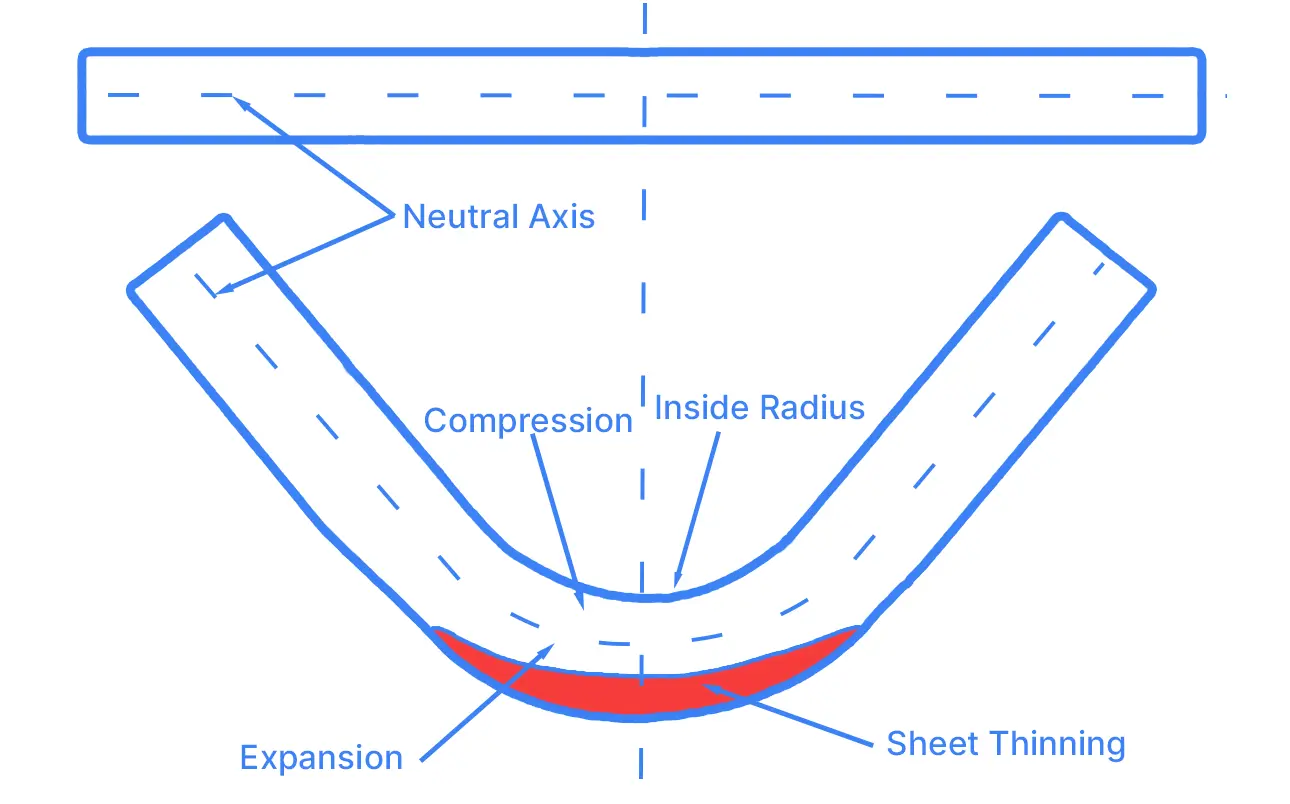

K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the material thickness where neither compression nor tension occurs during bending.

Specifically, K-factor is defined as the ratio of the neutral axis location to the material thickness. It typically ranges from 0.3 to 0.5.

Why K-factor Matters

Understanding K-factor is essential for several reasons:

- Bend Allowance Calculation: K-factor directly impacts the bend allowance, which is the length of the arc through the bend at the neutral axis. Accurate bend allowance calculations ensure your flat patterns are the correct size before bending.

- Part Accuracy: Using the wrong K-factor can lead to parts that are too long or too short after bending, potentially causing assembly issues or part rejection.

- Material Optimization: Proper K-factor calculations help minimize material waste by ensuring your initial flat patterns are sized correctly.

Note:

Factors Affecting K-factor

K-factor isn't a one-size-fits-all value. Several factors can influence it:

- Material Properties: Different materials have varying levels of ductility and strength, affecting how they stretch and compress during bending.

- Material Thickness: Thicker materials generally have a lower K-factor than thinner ones of the same type.

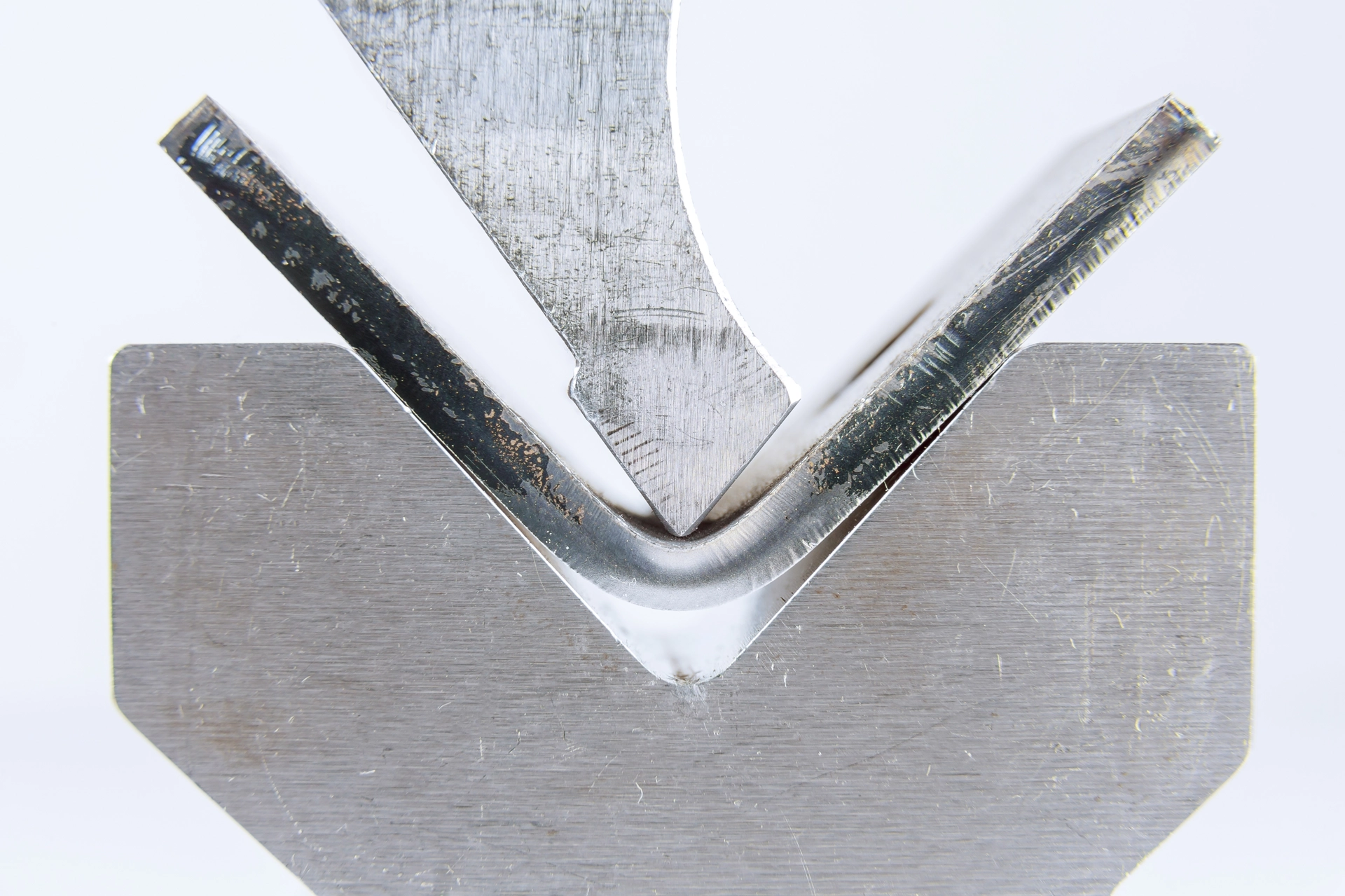

- Bend Radius: Tighter bend radii tend to result in a lower K-factor.

- Bending Method: The type of bending process (air bending, bottoming, coining) can impact the K-factor.

Determining the Right K-factor

While general guidelines and default values exist, the most accurate way to determine K-factor is through experimentation and measurement of actual bent parts. At Fabworks, we've invested significant time in testing and refining K-factors for various materials and thicknesses to ensure optimal accuracy in our sheet metal bending service.

For our customers, this means you don't need to worry about K-factor calculations when designing your parts. Our advanced manufacturing processes automatically account for the correct K-factor based on your specific material.

Here are the K-Factors we use at Fabworks

| Grade | Thickness | K-Factor |

|---|---|---|

No items. | ||

Simplifying Sheet Metal Design

Understanding K-factor is crucial for anyone involved in sheet metal design and manufacturing. However, we recognize that not every designer or engineer wants to delve into these complex calculations for every project.

That's why at Fabworks, we've streamlined the process. When you use our sheet metal bending service, you can focus on your design while we handle the technical details. Our expertise in K-factor application, combined with state-of-the-art CNC bending equipment, ensures your parts are bent with precision every time.

Whether you're working on a prototype or a large production run, you can trust that your sheet metal parts will be manufactured to the highest standards of accuracy. Simply upload your designs, and we'll take care of the rest, from K-factor calculations to final production.

In conclusion, while K-factor is a critical component of accurate sheet metal bending, partnering with an experienced manufacturer like Fabworks can simplify your design process and ensure consistently high-quality results. Focus on innovation in your designs, and let us handle the complexities of bending calculations and manufacturing precision.

Essential Checks Before Ordering Sheet Metal Parts

Optimize sheet metal designs with our pre-order checklist. Catch common errors and ensure manufacturability before submitting to Fabworks' laser cutting service.

Fast Track Your Project .

Seamless process, unparalleled precision, unbeatable speed. Turn your design into reality by beginning your journey with us today.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.